16 Jan As plastic is eclipsed by tightening industry legislation, Ronpak’s leading environmental efforts offer a focused look at managed sustainability and better practices in the commercial packaging space.

It's 2019, and staying afloat in the US plastics industry these days is getting much harder.

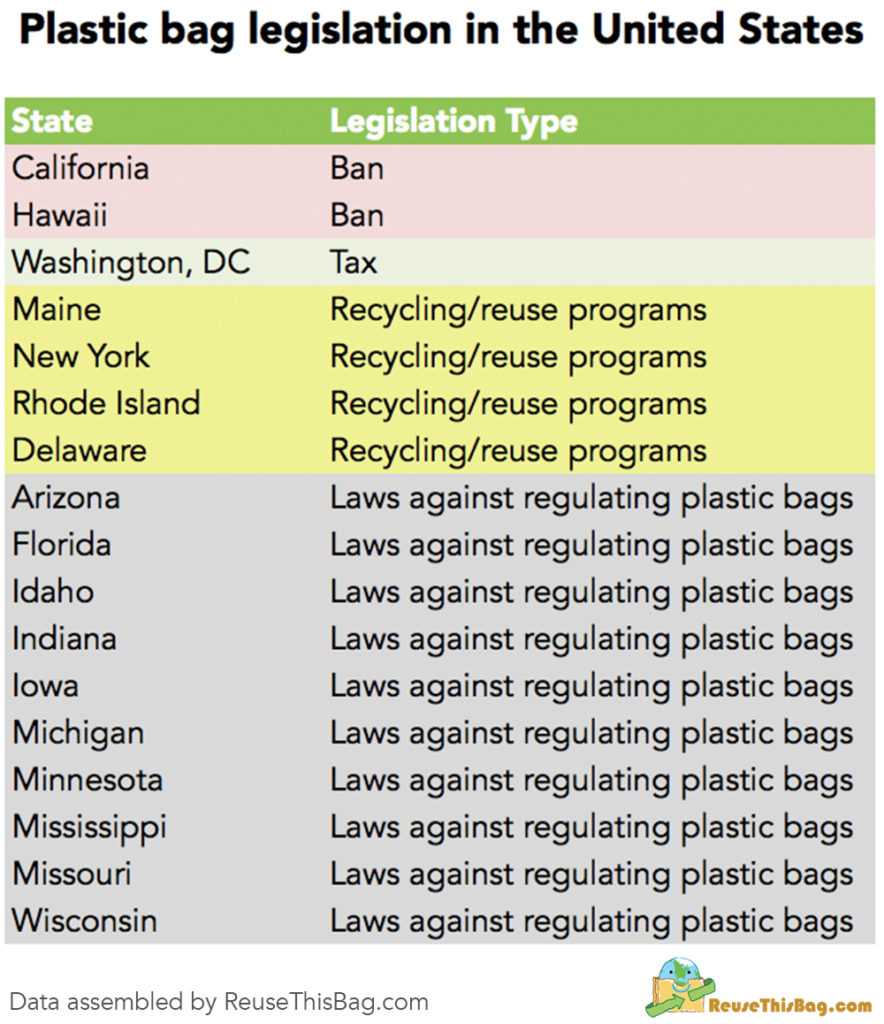

National state legislatures are on the move, writing and voting on tough new plastic bag bans on items such as the Single Use plastic bag, which is most commonly used in grocery stores at checkout. That means that scaling up and out in the plastics industry these days is a more difficult proposition and one that’s rapidly losing its’ appeal.

We all remember how Starbucks Coffee felt about their plastic straws; now with California and the rest of the West coast leading the charge, the entire plastics industry is coming under more intensified scrutiny with reams of new or pending legislation appearing in other states across the country.

These current and developing legislative bans or policy changes singling out plastics are unfortunate for plastics-based industries, but on the other side of that coin, these shifts are bringing about more opportunities for paper suppliers like Ronpak.

Prohibitions on “Single-use” shopping bags like the ones that you get at your typical retail store are the main driver in almost all the states working to ban plastic bags within this year – or next year. As states more clearly define their legal stance on plastic bag usage, many of the legal positions communities and municipalities will take are based upon observations of what California legislation has done in recent years.

California has some of the most aggressive laws in the country regarding recycling, environmental impact, sustainability, biodegradability and compostability of commercially produced retail and foods packaging.

Companies and brands are getting impacted with non-compostable end products.

Products that are “compostable” can be placed inside or with other decaying bio-degradable materials, eventually turning that product into a resulting material that has organic benefit. “Compostability” has now become a quantifiable attribute for commercially-produced products sold in particularly environmentally-conscious markets like California and the rest of the west coast.

Since the EPA considers composting or compostability a degree of recycling, the idea that products should have the capacity to be compostable has taken hold within the commercial packaging industries. Products that fail to meet the Compostable specification will start to feel the pinch. For example, in the recent past, a manufacturing customer was found to have products placed in 22 stores on the West coast; but because that particular product was non-compostable, that company was given three months to find an alternative to produce and then take to market. That’s three months – from zero to shelf. The result of these regulations? You will start to see product after product receive some sort of fine or penalty unless alternatives can be developed and produced as a replacement in time. That’s not very pleasant news for many products that never needed to consider what happens to products “post-use”, is it?

To American consumers, the soda tax wasn't ever a thing. But it is now. Cities are moving faster to target and ban plastics packaging.

• Berkeley, CA.

• Philadelphia, PA.

• San Francisco, CA.

• Oakland, CA.

• Albany, CA.

• Boulder, CO.

• Cook County, IL.

• Seattle, WA

The plastics industry continues to get hammered as more states ramp up their current or pending plastics legislation.

Policymakers are working throughout the industry to find and remedy manufacturing points of failure or non-compliance as related to food packagers and those standards. Many states are creating their own methods to oversee regulatory controls, taking cues from states like California, who has “led the pack” so to speak for years with focused and fairly aggressive legislation governing facility environmental impact, exhaust emissions, and even safety for surrounding habitat.

Policymakers are working throughout the industry to find and remedy manufacturing points of failure or non-compliance as related to food packagers and those standards. Many states are creating their own methods to oversee regulatory controls, taking cues from states like California, who has “led the pack” so to speak for years with focused and fairly aggressive legislation governing facility environmental impact, exhaust emissions, and even safety for surrounding habitat.

In one form or another, everyone seems to defer to California when it comes to making new policy. Even as the plastic industry competes, they are clearly getting singled out for the detrimental effects plastics can have on our environment.

California probably has more experience in environmental positions as this goes back to her Arnold Schwarzenegger days. He implemented several tools and monies to look into these environmental concerns. It’s not just aerosol industries; it extends across all sorts of chemical Industries or anything that may have an adverse effect on the environment. The result is that everybody wants to fall in line with California.

Following California's leading...

The West coast has traditionally reacted faster to the environmental impact of produced products. For instance, Washington state has a implemented a fee around plastic bottles for sodas. Washington established a 25 percent penalty on consumer sodas in order to fight & prevent obesity in younger people. So Washington citizens are now rewarded with an additional fee for purchasing a typical gas station soda.

Washington state, Oregon and other Pacific coast cities are moving ahead punishing plastic. Couched as a necessary health reform, plastic straws have been banned in all three states from top to bottom and at least 25 state legislatures have got new regulations ready before now to plan to ban plastic straws.

Another example of a complete statewide plastic bag ban can be found in Hawai’i, where all of its counties prohibit the usage of non-bio-degradable plastic bags (at checkout) as well as paper bags manufactured with >40% recycled material. Kauai, Maui and Hawai’i established plastic bans from 2011 through 2013; the city of Honolulu had bans in place by 2015. As state of Hawaii, for example, has banned single use plastic bags state-wide for years, now. Additionally, Hawaii is now pursuing legislation to get cigarette smoking banned inside the state by increasing the minimum smoking age to 100 years old!

The West coast has traditionally reacted faster to the environmental impact of produced products. For instance, Washington state has a implemented a fee around plastic bottles for sodas. Washington established a 25 percent penalty on consumer sodas in order to fight & prevent obesity in younger people. So Washington citizens are now rewarded with an additional fee for purchasing a typical gas station soda.

Washington state, Oregon and other Pacific coast cities are moving ahead punishing plastic. Couched as a necessary health reform, plastic straws have been banned in all three states from top to bottom and at least 25 state legislatures have got new regulations ready before now to plan to ban plastic straws.

Another example of a complete statewide plastic bag ban can be found in Hawai’i, where all of its counties prohibit the usage of non-bio-degradable plastic bags (at checkout) as well as paper bags manufactured with >40% recycled material. Kauai, Maui and Hawai’i established plastic bans from 2011 through 2013; the city of Honolulu had bans in place by 2015. As state of Hawaii, for example, has banned single use plastic bags state-wide for years, now. Additionally, Hawaii is now pursuing legislation to get cigarette smoking banned inside the state by increasing the minimum smoking age to 100 years old!

Ronpak Corporate Director

Quality, Environment & Sustainability

“I guess because to be completely honest California probably has more experience in this; it goes back to the Arnold Schwarzenegger days. He implemented all these tools & monies to look into this. It's not just this aerosol Industries; it’s all sorts of chemical industries & anything that may have an adverse effect on the environment.”

Ray Kitchens, Ronpak’s Corporate Director of Quality, Environmental & Sustainability, attends at least five conferences each calendar year on behalf of Ronpak in order to stay abreast of the paper and plastics industry policy changes and updates with respect to environmental and sustainability issues within the industry.

Some states move more quickly on enacting plastics bans or other prohibitions based in or around the environmental impact of commercial products. These sweeping changes mean the plastics industries are staying under regulatory scrutiny like never before; these new plastics legislative motions are pushing to eliminate plastic products – everything from plastic straws (like Starbucks) to even styrofoam products, but significant focus is given with respect to the ubiquitous Single Use plastic bags (typically present in a grocery checkout line). As a result of California legal precedents and other municipal changes, multiple states have already banned or are in the process of banning these single use plastic bags. Additionally, these motions have all been initiated within the last two years.

As you’re no doubt aware, plastic straws have also been banned in CA, OR & WA. But for 5 cents more, you could request a paper straw.

As bans continue in the service of health reforms, plastic straws have been targeted for elimination in all three states from top to bottom with additional state legislatures across the country ready to implement new laws targeting plastic straws. And even though consumers can request an alternative for a few cents more, California remains years ahead of everyone else in the “ban game”.

As the Quality Director for Ronpak, Mr. Kitchens gets updated monthly from the Food Service Packaging Institute with information covering new legislative issues, guidelines or policy changes that could imapct Ronpak facility operations moving forward. Even as many of these changes are being pushed by California and accepted by other states, Ronpak has been working consistently to adhere to these changing laws and successfully navigate the resulting landscape for both the paper and plastics sectors. In this way, Ronpak has made its commitment to being a better steward of the environment and continues to set goals year after year to not only meet the changing regulations – but to exceed them.

Today, food packaging products must be compostable in addition to retaining their recyclable capacity. Biodegradability is now the norm instead of the exception.

In today’s packaging manufacturing, everything must pass a Compostability Test – be it a paper or plastic product. Some Compostability tests can even take up to 18 months to conduct! Currently, Ronpak is already testing their commercial paper product lines for compostability and adherence to composting guidelines & standards. Plastics products, on the other hand, typically cannot pass similar Compostability testing.

How are these compostability tests performed? Compostability testing includes time lapse & video photography of product packaging to demonstrate how the bag itself degrades and composts over time. This is part of the 18-month testing cycle that Ronpak is already working towards with its own products. The compostability of each tested bag is then recorded & documented. There are no plastics content present in these types of industrial composted products, which ultimately gets sold to Lowe’s or Home Depot for consumer use.

Once Ronpak completes all their bag compostability testing, they will then be able to update each of their packaging products to show the “Compostable” logo and the “How-2-Recycle” stamp on all produced bags. This information helps teach the end-consumer how to get rid of the bag once they use it. A QR-type block code (read from any smartphone) instructs the consumer about recycling and post-use. In this way, Ronpak can continue to promote Consumer Responsibility even at the end of a product life cycle.

Once Ronpak completes all their bag compostability testing, they will then be able to update each of their packaging products to show the “Compostable” logo and the “How-2-Recycle” stamp on all produced bags. This information helps teach the end-consumer how to get rid of the bag once they use it. A QR-type block code (read from any smartphone) instructs the consumer about recycling and post-use. In this way, Ronpak can continue to promote Consumer Responsibility even at the end of a product life cycle.

Additionally, any time Ronpak brings on a new source supplier, that supplier is examined and audited to ensure that the new supplier adheres to Ronpak’s environmental and sustainability requirements. Ronpak is aware of all materials contained in their products from the supplier standpoint and there are no components of Ronpak products that are not biodegradable (with the exception of the shrink-wrap required for shipping pallets).

Any and all Ronpak suppliers must continually meet (and pass) all FDA requirements relating to the biodegradability of their source products. All Ronpak suppliers consequently submit to Ronpak what’s known as a “Letter of Guarantee”, that demonstrates each supplier’s FDA compliance status. For each Ronpak supplier of record, those supply sources have stated and subsequently proven they meet or exceed all FDA & government requirements with respect to food-based paper packaging products.

Testing everything.

Ronpak enlists the Compostability testing services of BPI – North America’s leading certifier of compostable products and packaging to review and certify that all Ronpak-produced client food packaging containers and paper products adhere to the compostable requirements now demanded of food packaging sources.

Adhering to best practices.

The Biodegradable Products Institute’s Certification program ensures that all products & packaging that show the BPI logo have been independently tested, certified and verified according to scientifically-based accepted standards.

Ronpak commits itself to meet or exceed all environmental rules and regulations in the paper products manufacturing industry and to strive to protect our environment through sound sustainability management practices and decisions.

Ronpak will prevent immediate and nearby pollution by striving to minimize waste generation and resource consumption.

Ronpak will establish and evaluate (in timely fashion) achievable environmental & sustainability performance goals to ensure continual improvement of its commercial packaging products.

Ronpak is dedicated to the practice of sound environmental stewardship and the promotion of health, safety and the well being of our shared planet and our family of employees. These values originate with Ronpak’s top management team, and are emphasized through all levels of responsibility within the company.

Sustaining the environment is more than just good business.

It's good stewardship of the

planet that we all share.

As such, Ronpak agrees to:

• Meet or exceed all applicable federal, state, and local environmental, safety and health standards.

• Provide a workplace free of recognized hazards and maintain healthy working conditions for all employees.

• Monitor all facilities (LA/CA/NJ) for prevention of excess pollution.

• Participate in recycling and compostability to the greatest practical extent to reduce impact on landfills and promote recovery of valuable resources.

• Convey to our clients, associates, vendors and the public our strong environmental, safety and health commitment.

• Strive to continuously improve our commitment to the above-stated principles through the exercise of our ongoing certifications such as SGS, NSF, SQF ISO 140001 & SFI, improved technology, production facility or equipment upgrades – and due diligence.